Purchasing hotline:886-4-23286708

上一张

下一张

Consultation hotline00886-4-23286708

Electric vehicles symbolize the contemporary environmental consciousness. To resonate with this, we present our eco-friendly, fast-drying coating tailor-made for electric vehicles, blending efficiency with cutting-edge innovation. What's more, our coating air-dries in a mere 10-30 minutes, eliminating the hassle of extra curing. Our unique palette, spanning from classic to trendy shades, ensures your EV retains a fresh appearance.

●Primer Coating:

Specially formulated for electric vehicles, our primer boasts an eco-centric recipe, significantly reducing

VOC emissions. Its exceptional adhesion and enhanced wear resistance lay a sturdy foundation for the

topcoat.

● Colored Coating:

We put forth a vibrant spectrum of color choices, from timeless classic black to crisp white, instilling

unparalleled personality into your EV. The durable hues combined with resistance to extreme climates

ensure the vehicle retains a commendable appearance for the long haul.

●Clear Coating:

Designed specifically for electric vehicles, this top layer not only adds profound luster but more crucially, it

layers on added protection against chemical corrosion and adverse weather. Mindful of cost-efficiency, it

requires no extra drying, substantially lowering production expenses.

|

Product Specifications |

Main Component: Water-basedTP system |

Diluent: Pure water |

|

Mixing Ratio |

1 part |

0.3-0.5 parts |

|

Filter Mesh |

Using a 200-300 mesh sieve |

|

|

Spray Gun, Air Pressure |

3-4gf/cm2 |

|

|

Film Thickness |

10±2um |

|

|

Drying Method |

Air dry Note: For accelerated curing ( Bake at 60°C for 30 minutes) |

|

|

Packaging Conditions |

After stabilizing at 60°C for 30 minutes, allow 3-5 hours for complete cooling before packaging. |

|

|

Physical Testing Conditions |

60°C (2-4 hrs) or 80°C (1-2 hrs), stabilize for 4-6 hrs, then proceed with physical tests. |

|

|

Suitable Substrates |

Metal hardware、Metal products、ABS、ABS+PC、PC、PS、PVC. |

|

|

Test Items |

Test Conditions |

Test Results |

|

|

1 |

Adhesion |

The sample is placed flat and scored both horizontally and vertically using a 100-grid knife. After cleaning the scored section, 3M#610 tape is applied over the grid. The tape is then pulled off at a 45° angle three times, resulting in a 5B adhesion rating. |

5B |

|

2 |

Hardness |

Sharpen a Mitsubishi H-grade pencil on sandpaper. Apply 500g weight and glide at a 45° angle from F to H. Ensure no scratches |

F-H No scratches |

|

3 |

Film Thickness |

Electronic coating thickness gauge |

10±2um |

|

4 |

Alcohol Resistance Test |

Rubbing Material: Cloth saturated with 99.5% alcohol. Load: 500g. Rubbing Distance: 3cm per cycle. Frequency: 30 cycles per minute. Criteria: The coating should exhibit no exposure of the underlying material (paint) after more than 200cycles. |

No substrate exposure observed |

|

5 |

High Temperature and Humidity Resistance |

Exposed to 65℃ and 95% humidity for 120 hours, followed by a 6-hour recovery at room temperature. Post-examination shows no abnormalities with a 5B pencil hardness test result. |

No visible abnormalities, 5B hardness achieved. |

|

6 |

High Temperature Storage

|

Stored in a 70℃ environment for 48 hours, then allowed 4 hours to return to room temperature. Post-examination shows no abnormalities with a 5B pencil hardness test result. |

No visible abnormalities, 5B hardness achieved. |

|

7 |

Low Temperature Storage

|

Placed in a -40℃ environment for 48 hours, followed by a 4-hour recovery at room temperature. Post-examination shows no abnormalities with a 5B pencil hardness test result. |

No visible abnormalities, 5B hardness achieved. |

|

8 |

Thermal Shock Resistance |

Alternated between 80℃ and -40℃, each temperature held for 1.5 hours with a 20-minute transition time, for a total of 20 cycles. Allowed 4 hours of recovery at room temperature. The surface should show no discoloration, blistering, peeling, shedding, or gloss variance. |

No visible abnormalities, 5B hardness achieved. |

|

9 |

Temperature and Humidity Cycling

|

Alternated between 65℃ at 95% humidity and -40℃, each condition held for 1.5 hours with a 20-minute transition time, for a total of 20 cycles. Allowed 4 hours of recovery at room temperature. The surface should show no discoloration, blistering, peeling, shedding, or gloss variance. |

No visible abnormalities, 5B hardness achieved. |

Related Products

Related Products

No Baking, Yet Outstanding Shine!

Waterborne Coatings (Air-drying Coatings) Learn More

Paint the future, metals more dazzling.

Waterborne Coatings (Air-drying Coatings) Learn More

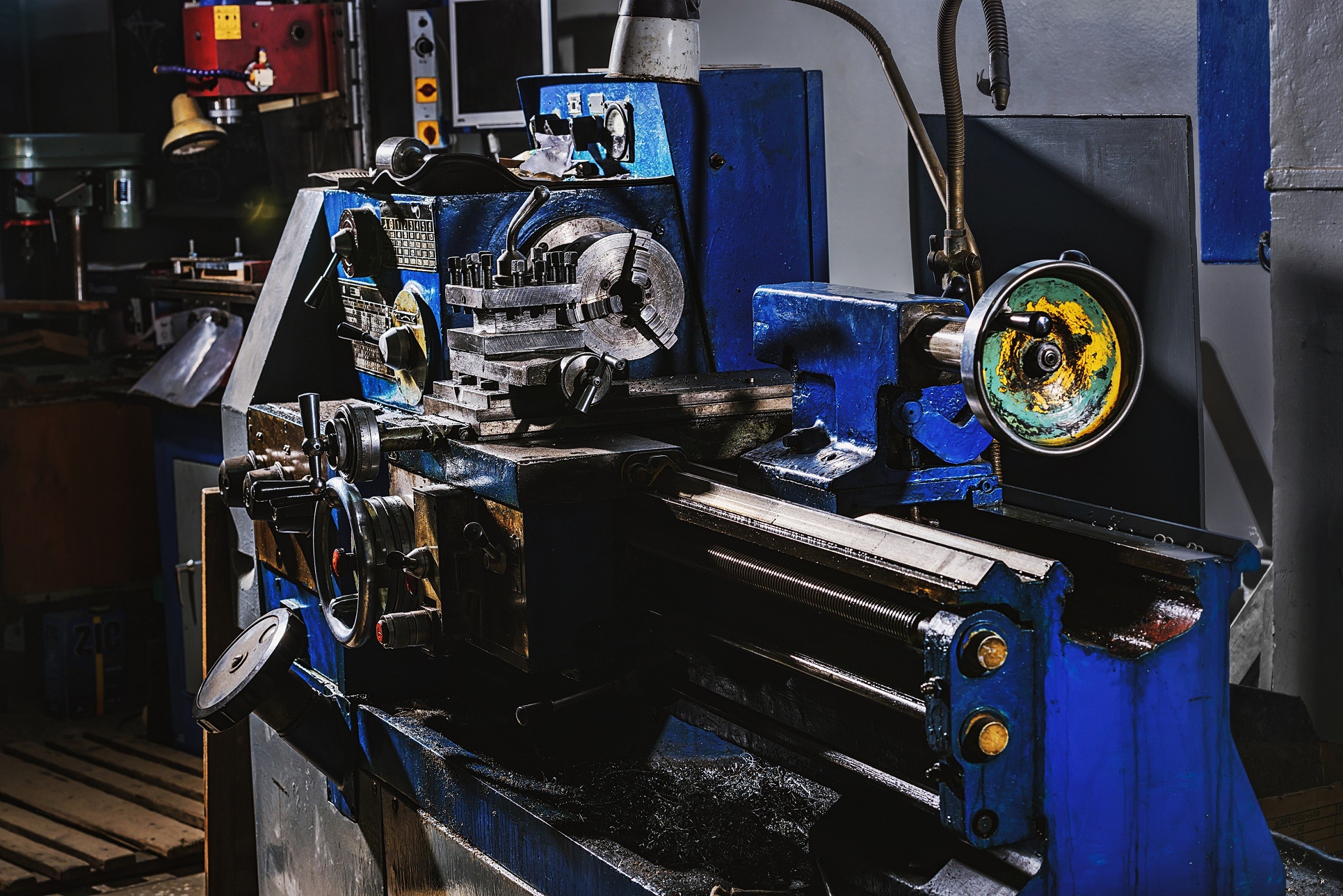

Professional coating, superior machinery.

Waterborne Coatings (Air-drying Coatings) Learn More