Purchasing hotline:886-4-23286708

上一张

下一张

Consultation hotline00886-4-23286708

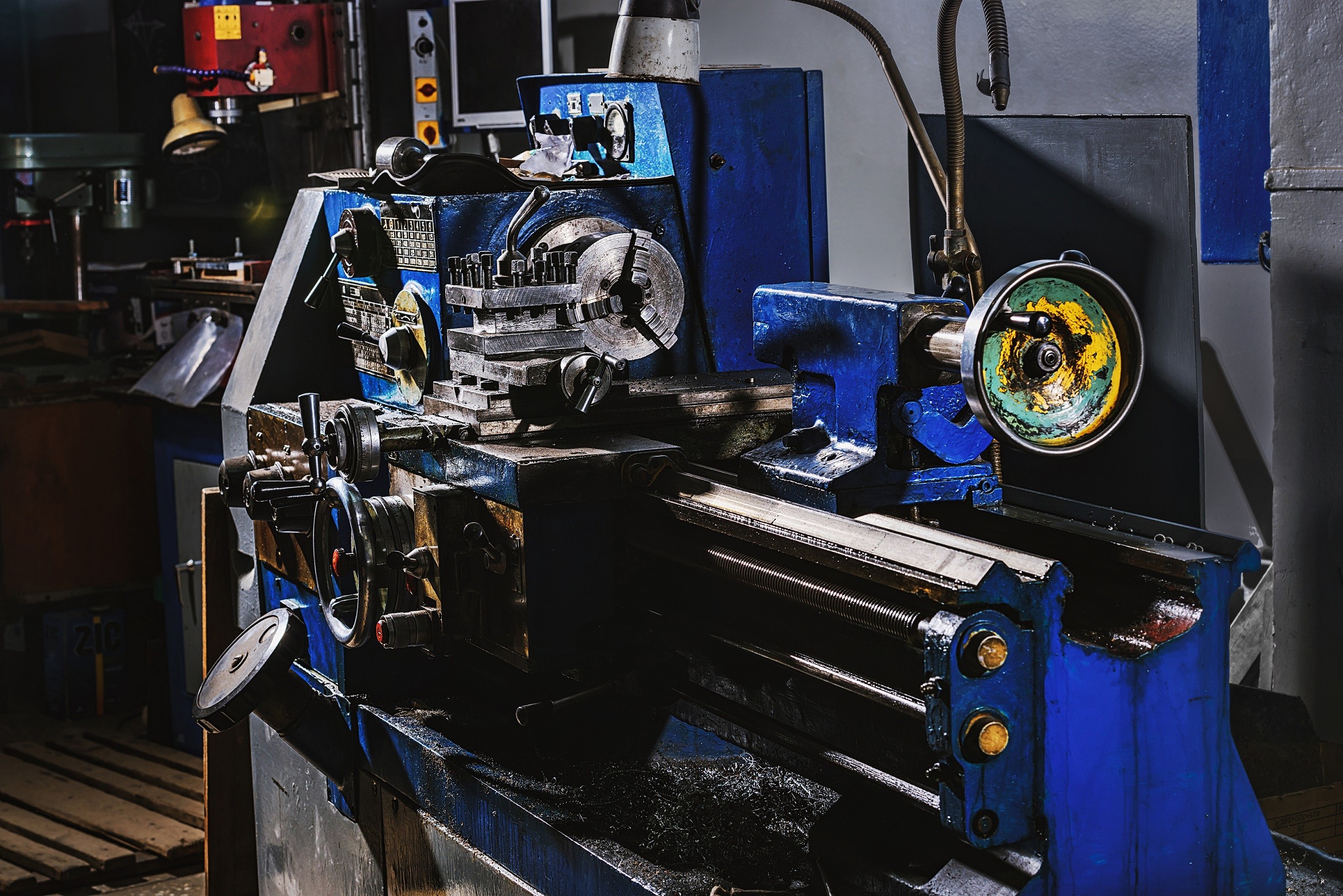

Machine tool equipment is crucial in the production process. To address the multifaceted requirements of modern manufacturing, we have introduced a Water-Based Self-Drying Coating tailored for machine tool equipment. Specifically conceived for large-scale products where traditional curing proves challenging, this coating comes with a plethora of advantages, offering paramount protection for your machinery.

●Primer Coating:

Made predominantly with water as its solvent, this coating substantially reduces VOC emissions,

reflecting a pronounced environmental commitment. It dries naturally in a short span, boosting production

efficacy immensely. Its superior adhesion enables a firm bond with various machine tool materials,

including metals and plastics.

● Colored Coating:

To enhance the aesthetic of machine tools, we offer a variety of color and gloss choices. This paint is not

only effective against mechanical wear but also exhibits remarkable corrosion resistance, protecting

against chemical agents like coolants and oils.

●Clear Coating:

Beyond granting an additional luster to machine tools, this coating primarily lays down a protective barrier

against high temperatures, chemical corrosion, and adverse weather. Plus, it air-dries within 10-30

minutes, eliminating the need for supplementary drying apparatuses.

|

Product Specifications |

Main Component: Water-based TP system |

Diluent: Pure water |

|

Mixing Ratio |

1 part |

0.3-0.5 parts |

|

Filter Mesh |

Using a 200-300 mesh sieve |

|

|

Spray Gun, Air Pressure |

3-4gf/cm2 |

|

|

Film Thickness |

10±2um |

|

|

Drying Method |

Air dry Note: For accelerated curing ( Bake at 60°C for 30 minutes) |

|

|

Packaging Conditions |

After stabilizing at 60°C for 30 minutes, allow 3-5 hours for complete cooling before packaging. |

|

|

Physical Testing Conditions |

60°C (2-4 hrs) or 80°C (1-2 hrs), stabilize for 4-6 hrs, then proceed with physical tests. |

|

|

Suitable Substrates |

Metal hardware、Metal products、ABS、ABS+PC、PC、PS、PVC. |

|

|

Test Items |

Test Conditions |

Test Results |

|

|

1 |

Adhesion |

The sample is placed flat and scored both horizontally and vertically using a 100-grid knife. After cleaning the scored section, 3M#610 tape is applied over the grid. The tape is then pulled off at a 45° angle three times, resulting in a 5B adhesion rating. |

5B |

|

2 |

Hardness |

Sharpen a Mitsubishi H-grade pencil on sandpaper. Apply 500g weight and glide at a 45° angle from F to H. Ensure no scratches |

F-H No scratches |

|

3 |

Film Thickness |

Electronic coating thickness gauge |

10±2um |

|

4 |

Alcohol Resistance Test |

Rubbing Material: Cloth saturated with 99.5% alcohol. Load: 500g. Rubbing Distance: 3cm per cycle. Frequency: 30 cycles per minute. Criteria: The coating should exhibit no exposure of the underlying material (paint) after more than 200cycles. |

No substrate exposure observed |

|

5 |

High Temperature and Humidity Resistance |

Exposed to 65℃ and 95% humidity for 120 hours, followed by a 6-hour recovery at room temperature. Post-examination shows no abnormalities with a 5B pencil hardness test result. |

No visible abnormalities, 5B hardness achieved. |

|

6 |

High Temperature Storage

|

Stored in a 70℃ environment for 48 hours, then allowed 4 hours to return to room temperature. Post-examination shows no abnormalities with a 5B pencil hardness test result. |

No visible abnormalities, 5B hardness achieved. |

|

7 |

Low Temperature Storage

|

Placed in a -40℃ environment for 48 hours, followed by a 4-hour recovery at room temperature. Post-examination shows no abnormalities with a 5B pencil hardness test result. |

No visible abnormalities, 5B hardness achieved. |

|

8 |

Thermal Shock Resistance |

Alternated between 80℃ and -40℃, each temperature held for 1.5 hours with a 20-minute transition time, for a total of 20 cycles. Allowed 4 hours of recovery at room temperature. The surface should show no discoloration, blistering, peeling, shedding, or gloss variance. |

No visible abnormalities, 5B hardness achieved. |

|

9 |

Temperature and Humidity Cycling

|

Alternated between 65℃ at 95% humidity and -40℃, each condition held for 1.5 hours with a 20-minute transition time, for a total of 20 cycles. Allowed 4 hours of recovery at room temperature. The surface should show no discoloration, blistering, peeling, shedding, or gloss variance. |

No visible abnormalities, 5B hardness achieved. |

Related Products

Related Products

Concrete Perfect Partner: Epoxy Floor Coating.

Learn More

Wheels turn, Earth smiles.

Learn More

Infusion Type Epoxy Resin: Unleashing Superior Performance

Learn More

With the increasing global attention to environmental issues, we have collaborated with leading manu...

Learn More

Where Every Turn Radiates Refinement.

Learn More