Purchasing hotline:886-4-23286708

上一张

下一张

Consultation hotline00886-4-23286708

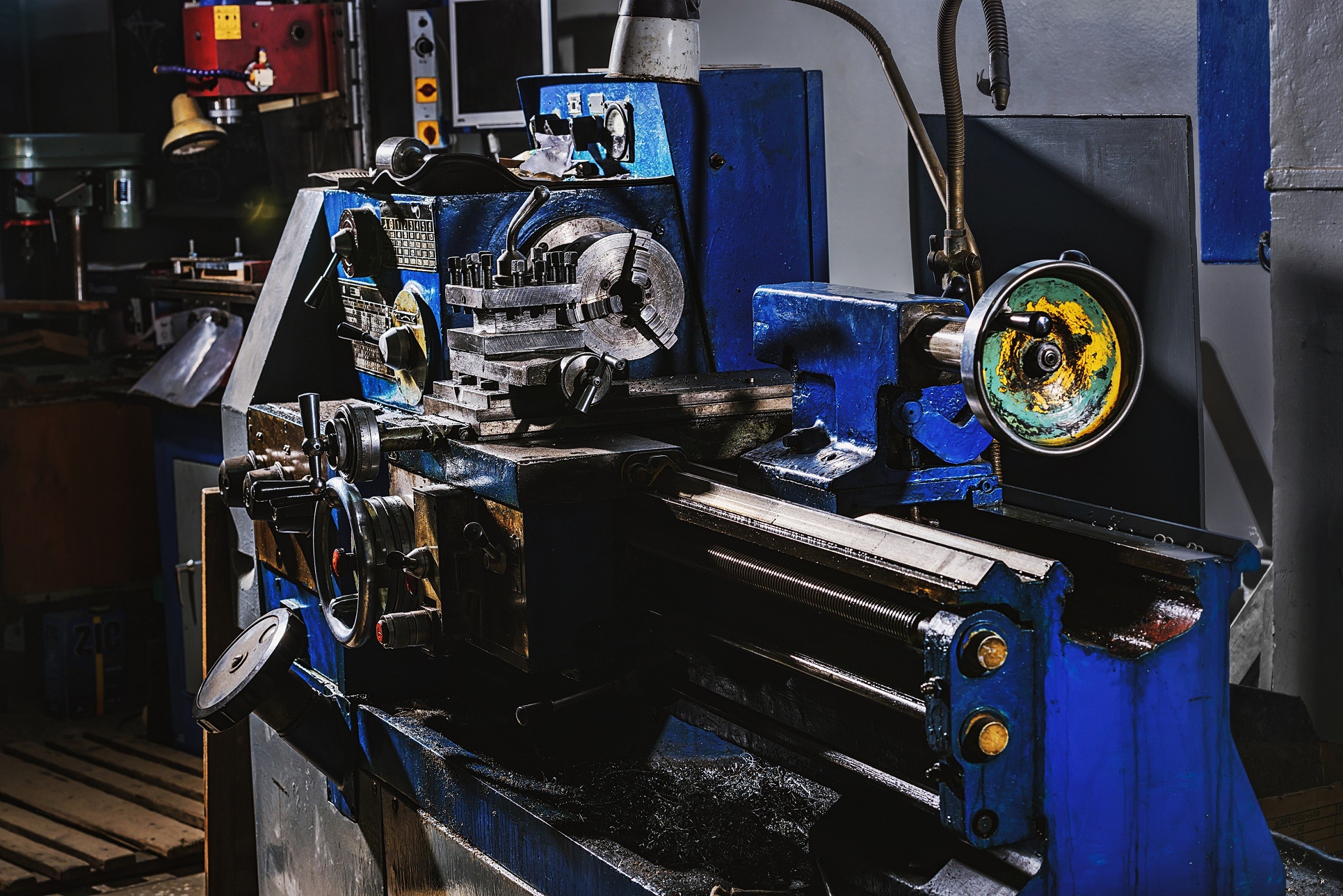

In the ever-evolving realm of industrial manufacturing, we have developed a Water-Based Self-Drying Metal Coating meticulously crafted for a variety of large-scale metal products. This innovative solution boasts rapid natural drying, eliminating the necessity for supplemental heat treatments or baking. In addition, it ensures exceptional adhesion and enduring toughness. With its twin pillars of environmental sustainability and cost efficiency, this coating emerges as the prime choice for metal product finishing.

●Primer Coating:

Crafted with water as the primary solvent, this primer adheres to stringent environmental standards. It

promises swift drying and superior adhesion, ensuring long-lasting durability on metal surfaces.

● Colored Coating:

Unyielding against environmental factors like sunlight and temperature variations, this coating preserves

its vibrant hues. Its efficient performance also cuts down production costs.

●Clear Coating:

Offering unmatched chemical and temperature stability, this clear coat self-dries within 10-30 minutes,

adding a brilliant sheen to the final product.

|

Product Specifications |

Main Component: Water-based TP system |

Diluent: Pure water |

|

Mixing Ratio |

1 part |

0.3-0.5 parts |

|

Filter Mesh |

Using a 200-300 mesh sieve |

|

|

Spray Gun, Air Pressure |

3-4gf/cm2 |

|

|

Film Thickness |

10±2um |

|

|

Drying Method |

Air dry Note: For accelerated curing ( Bake at 60°C for 30 minutes) |

|

|

Packaging Conditions |

After stabilizing at 60°C for 30 minutes, allow 3-5 hours for complete cooling before packaging. |

|

|

Physical Testing Conditions |

60°C (2-4 hrs) or 80°C (1-2 hrs), stabilize for 4-6 hrs, then proceed with physical tests. |

|

|

Suitable Substrates |

Steel (Carbon, Stainless)、Aluminum、Copper & Copper Alloys (Bronze, Brass)、Zinc (Galvanized Steel)、Iron (Cast, Ductile). |

|

|

Test Items |

Test Conditions |

Test Results |

|

|

1 |

Adhesion |

The sample is placed flat and scored both horizontally and vertically using a 100-grid knife. After cleaning the scored section, 3M#610 tape is applied over the grid. The tape is then pulled off at a 45° angle three times, resulting in a 5B adhesion rating. |

5B |

|

2 |

Hardness |

Sharpen a Mitsubishi H-grade pencil on sandpaper. Apply 500g weight and glide at a 45° angle from F to H. Ensure no scratches |

F-H No scratches |

|

3 |

Film Thickness |

Electronic coating thickness gauge |

10±2um |

|

4 |

Alcohol Resistance Test |

Rubbing Material: Cloth saturated with 99.5% alcohol. Load: 500g. Rubbing Distance: 3cm per cycle. Frequency: 30 cycles per minute. Criteria: The coating should exhibit no exposure of the underlying material (paint) after more than 200cycles. |

No substrate exposure observed |

|

5 |

High Temperature and Humidity Resistance |

Exposed to 65℃ and 95% humidity for 120 hours, followed by a 6-hour recovery at room temperature. Post-examination shows no abnormalities with a 5B pencil hardness test result. |

No visible abnormalities, 5B hardness achieved. |

|

6 |

High Temperature Storage

|

Stored in a 70℃ environment for 48 hours, then allowed 4 hours to return to room temperature. Post-examination shows no abnormalities with a 5B pencil hardness test result. |

No visible abnormalities, 5B hardness achieved. |

|

7 |

Low Temperature Storage

|

Placed in a -40℃ environment for 48 hours, followed by a 4-hour recovery at room temperature. Post-examination shows no abnormalities with a 5B pencil hardness test result. |

No visible abnormalities, 5B hardness achieved. |

|

8 |

Thermal Shock Resistance |

Alternated between 80℃ and -40℃, each temperature held for 1.5 hours with a 20-minute transition time, for a total of 20 cycles. Allowed 4 hours of recovery at room temperature. The surface should show no discoloration, blistering, peeling, shedding, or gloss variance. |

No visible abnormalities, 5B hardness achieved. |

|

9 |

Temperature and Humidity Cycling

|

Alternated between 65℃ at 95% humidity and -40℃, each condition held for 1.5 hours with a 20-minute transition time, for a total of 20 cycles. Allowed 4 hours of recovery at room temperature. The surface should show no discoloration, blistering, peeling, shedding, or gloss variance. |

No visible abnormalities, 5B hardness achieved. |

Related Products

Related Products

Professional coating, superior machinery.

Waterborne Coatings (Air-drying Coatings) Learn More