Welcome to our advanced coating production center, where we utilize cutting-edge production technology and stringent quality management systems to provide customers with highly consistent and outstanding performance coating products. Now, follow us as we delve into this technologically superior production area.

Ensuring product quality and staff safety, our raw material storage area is meticulously categorized for optimal safety and environmental protection. Equipped with advanced safety facilities and monitoring systems, we strive to prevent potential risks associated with material storage.

● Class A Storage Zone: This space is reserved for highly flammable and explosive materials, and we enforce the strictest safety measures to ensure security.

● Class B Storage Zone: Here, we store materials with moderate hazards, implementing comprehensive safety management practices.

● Class C Storage Zone: We safely store liquids with a flashpoint above 60°C and combustible solids, maintaining high standards of safety management.

● Class D Storage Zone: This area is designated for handling materials at high temperatures or in a molten state, with all operations conducted under strict safety supervision.

● Solid Waste Storage Area: We adhere rigorously to environmental regulations, ensuring all solid waste is properly stored and managed.

● Chemical Product Tank Farm: A storage facility for a variety of solvents, resins, and other chemical raw materials and products.

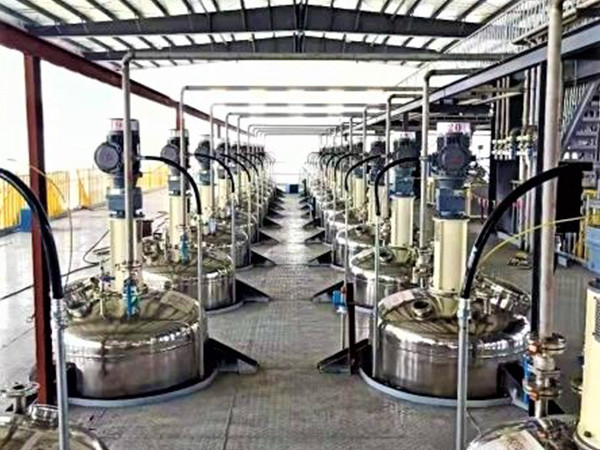

In our technologically advanced Mixing and Grinding Zone, we meticulously design each process to ensure that from raw materials to finished products, every type of coating exhibits its best performance.

Resin Preparation

● Equipment & Functionality: Our high-position resin tank is specifically engineered for the precise preparation of various resins, laying a solid foundation for coating production.

● Application Range: Includes a comprehensive range of products such as alkyd, acrylic, epoxy, polyurethane, polyamide, polyester, and water-based coatings.

Solvent Mixing

● Equipment & Functionality: With the solvent high-position tank, we mix a variety of solvents, optimizing the pre-treatment process for resins and pigments.

● Application Range: Supports production lines for all types of coatings.

Pre-mixing and Dispersion

● Equipment & Functionality: Utilizing mixing kettles and dispersers, we ensure pre-mixing and efficient dispersion, achieving uniform pigment distribution.

● Application Range: Covers a broad spectrum of coating types.

Grinding and Tinting

● Equipment & Functionality: High-end equipment like sand mills and grinding mills are used to guarantee each batch of coating has a consistent texture and quality.

● Application Range: Accommodates an extensive product line, including both oil-based and water-based coatings.

Environmental Protection and Quality Control

By employing enclosed mixing and grinding equipment, we minimize material leakage and mitigate environmental impact, showcasing our steadfast commitment to sustainability. The use of real-time monitoring tools, such as online particle size analyzers and colorimeters, ensures product quality's stability and reliability, fostering complete trust from our customers.

In our Adjustment Area and Inspection Area, we utilize advanced equipment and extensive experience to finely tune and comprehensively inspect our coatings, ensuring they meet customer requirements in multiple dimensions such as color, consistency, gloss, and pH value. We are committed to providing exceptional coating quality and meeting our customers' demands for personalized colors.

Adjustment Area

● Equipment and Functions: We employ advanced equipment such as tinting machines, spectrophotometers, and gloss meters to precisely match and verify coating colors, ensuring color consistency and high quality in every batch.

● Application Scope: Suitable for meeting the custom color needs of customers in industries such as manufacturing, automotive, and construction.

Associated image:

inspection Area

● Equipment and Functions:

Distributed Control System: Precisely monitors and regulates the production process to ensure product quality.

Safety Instrumented System: Continuously monitors potential hazards to prevent accidents and ensure workplace safety.

Coating Mixer (with dust extraction system): Maintains a clean production environment and prevents contamination of the coating materials.

Stability and Oven Temperature Tester: Verifies the performance of the coatings, ensuring their stability under various environmental conditions.

● Application Scope: Comprehensive coverage of all types of coatings, ensuring we meet the high standards required by different industries and applications.

Associated image:

In our Filtration and Filling Area, we employ high-efficiency and advanced equipment for stringent quality control, ensuring every batch of coating meets the highest standards. We are dedicated to providing pure, high-quality products to meet the needs of our global clientele.

Filtration Area:

● Equipment and Functions:

High-Pressure Filter: Effectively removes high-density impurities from the coating, ensuring product purity.

Stainless Steel Portable Filter: Flexible and efficient, it can be quickly adjusted according to production needs.

Vibrating Sieve Machine: Utilizes vibration technology to accurately separate particles and impurities from the coating.

● Application Scope:

Suitable for all types of coating that require the removal of undispersed particles or other impurities, ensuring purity and high quality in every batch.

Filling Area:

● Equipment and Functions:

Automatic Packaging Machine: Efficiently seals the coating, enhancing production efficiency.

Automatic Batching Machine and Filling Machine: Ensures precise coating formulation and filling volume.

Automatic Electronic Scale and Floor Scale: Accurately measures coating weight, ensuring product quality.

● Application Scope:

Suitable for the final packaging and transportation of various coating products, ensuring a fast, accurate, and efficient production process.

Associated image:

Powder Coating Production Area Overview

● Raw Material Selection Area: Consistency in quality starts from the source with our premium selection of resins, pigments, and additives.

● Precise Mixing & Extrusion Area: Uniform mixing and flawless integration of all materials at high temperatures are guaranteed by our expertly calibrated equipment.

● Compacting, Crushing, and Grinding Area: Post-extrusion, the material is compacted, crushed, and ground to achieve the perfect particle size, ready for application.

● Stringent Quality Control Lab: Every batch undergoes rigorous testing in our Quality Control Lab, ensuring it meets and exceeds industry standards.

● Efficient Packaging and Delivery Area: Our products are swiftly packaged and stored, ready for rapid dispatch to meet the needs of our clients worldwide.

Through meticulous management and maintenance of these key areas, we ensure that our powder coatings consistently maintain a high quality, meeting and exceeding customer expectations.

In our Environmental Protection Equipment Zone, we seamlessly integrate state-of-the-art technology with a profound commitment to sustainable practices and the well-being of our workforce.

● Key Equipment and Functions:

Regenerative Catalytic Oxidizer (RCO): This device transforms harmful emissions from our factory, mitigating environmental pollution and enhancing air purity.

Dust Collector (Spray Coating Booth): This equipment reduces the impact of dust on both the environment and worker health, ensuring a dust-free workspace.

Wastewater Treatment Project: Our system treats industrial wastewater using various methods to meet discharge or reuse standards.

Environmental Monitoring Equipment: This includes data acquisition systems and portable gas detectors, which continuously monitor air quality, water quality, and more, preventing exposure to toxic gases and ensuring both environmental and human health.

Pollutant Treatment Equipment: This category includes photo-oxygen machines and activated carbon adsorption devices, which treat harmful substances in the air, reduce environmental pollution, and improve health and safety conditions at work.

● Application Scope:

We take comprehensive measures to minimize our environmental impact, protect employee welfare, and uphold our global environmental responsibilities.

In the Research and Development & Quality Control Area, our goal is to ensure product quality while driving technological innovation.

● R&D Area: Bringing together a top-notch R&D team, dedicated to the development of new products and the optimization of existing ones.

● Spraying Room: Simulating real application environments to conduct comprehensive tests on coating performance.

● Product Showroom: Displaying our mature products and innovative achievements, allowing customers to intuitively understand our product quality and technical level.

● Sample Management Room: Here, we meticulously manage and store samples to ensure the accuracy of experiments and tests. Additionally, we retain color samples from each batch of deliveries for future quality tracking and customer service.

● Testing Room: Equipped with advanced equipment for rigorous quality testing, ensuring the stability and reliability of each batch of products.

Our laboratory equipment includes spectrophotometers, gas chromatographs, laser particle size analyzers, etc., capable of conducting various tests such as color consistency, wear resistance, and curing time.

Our goal is to continuously improve product quality and meet customer needs through scientific methods and precise equipment.